How do we do it?

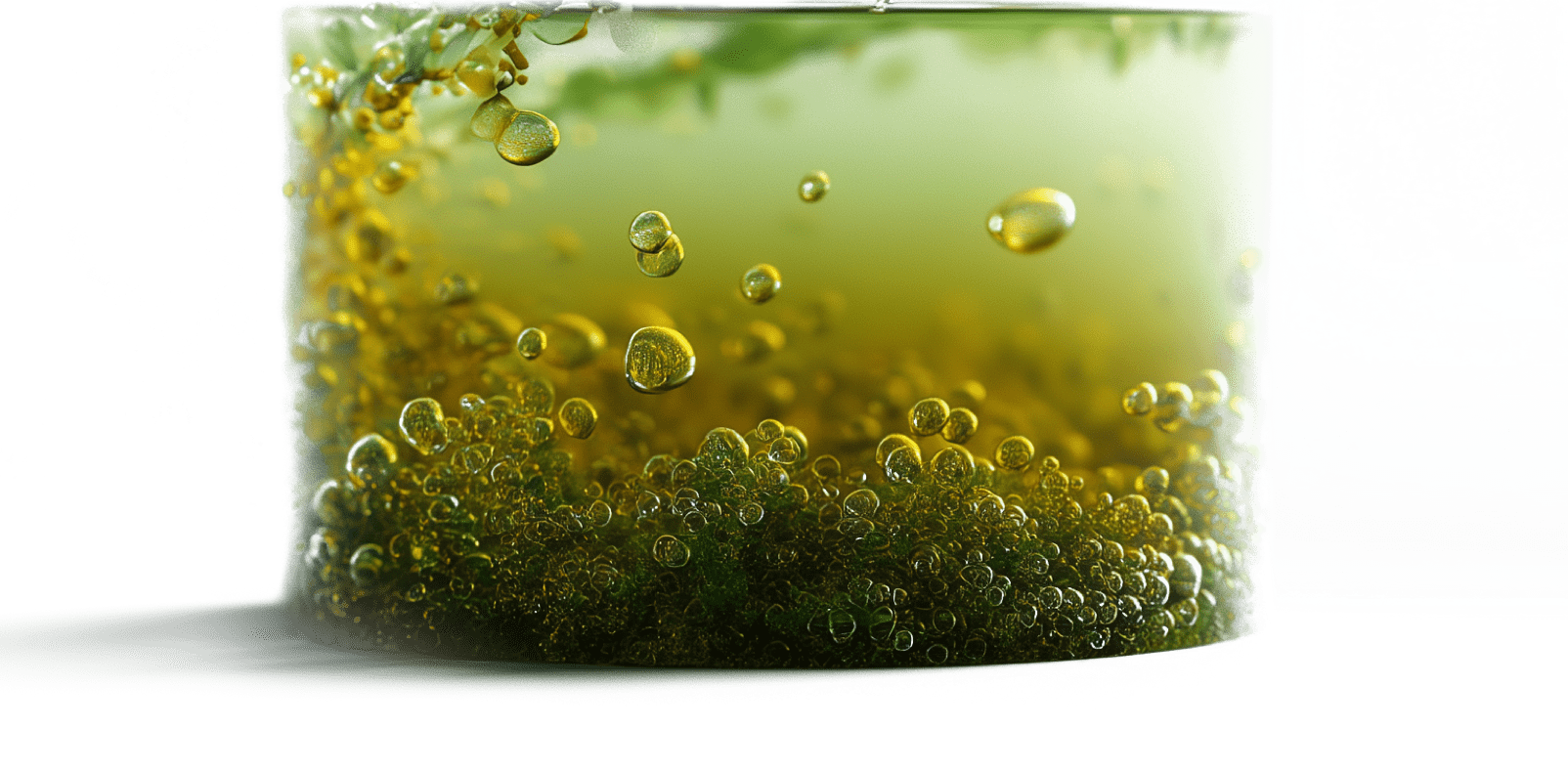

We use proprietary solvent and bioprocessing technology to convert non-food biomass into fermentable sugars, high-value intermediates, and drop-in fuels.

ASPIRE™ Technology

Erg Bio’s Aspire™ Technology utilizes a unique low-temperature solvent pretreatment to extract cellulosic material from diverse sources like agricultural waste, forestry and wood waste, and solid municipal waste including mixtures. With the ability to process over 40 different feedstocks, it yields higher fermentable sugars at low capital and operating expenses.

ASPIRE™: Advanced Solvent Pretreatment for Integrated BioREfinery

Erg Bio’s ASPIRETM Technology is truly feedstock agnostic and works on over 40 agriculture residues, forest/woody waste and municipal solid waste as well as dedicated energy crops with the ability to even use mixtures of feedstocks. This makes the technology prime to leverage the 1.1 to 1.5 billion tons of biomass available in the U.S. alone.

Unlike traditional pretreatment systems that rely on high heat, high pressure, corrosive chemicals, or costly equipment and multiple unit operations, ASPIRE™ uses a distillable solvent system that operates under mild conditions and recycles more than 99% of its components. This allows efficient sugar recovery, lower capital costs, and compatibility with existing industrial infrastructure.

By combining this solvent system with engineered yeast that can both hydrolyze and ferment, Erg Bio closes the loop from feedstock to finished product — reducing process complexity while expanding what’s possible with biomass.